The wall sandwich panels are constructed with a rigid PU foam core, which is securely attached to the support structure using hidden contact methods. The well-designed plate edges allow for discreetly concealing the mounting screws within a specially contoured lock that covers the adjacent panel. As a result, the building facade remains free from any visible fasteners, creating a cohesive and sophisticated appearance.

Sandwich panel – application

- Commercial facilities

- Industrial facilities

- Halls

- Agricultural facilities.

- Logistics centers

- Warehouses

Sandwich panel — advantages

1. Enhanced fire resistance and dimensional stability provide a distinct advantage.

2. Superior mechanical and thermal properties contribute to its exceptional performance.

3. Its excellent insulation capabilities, coupled with low thermal conductivity (l:21mW/mK), make it highly efficient.

4. High productivity and good curing performance ensure minimal waste during the manufacturing process.

5. With its good processability, it exhibits strong adhesion under appropriate conditions.

6. The lightweight nature of this material extends the lifespan of buildings where it is used.

7. Made from 100% pure raw materials, it offers systems designed for different flammability classes (PIR, B2, B3).

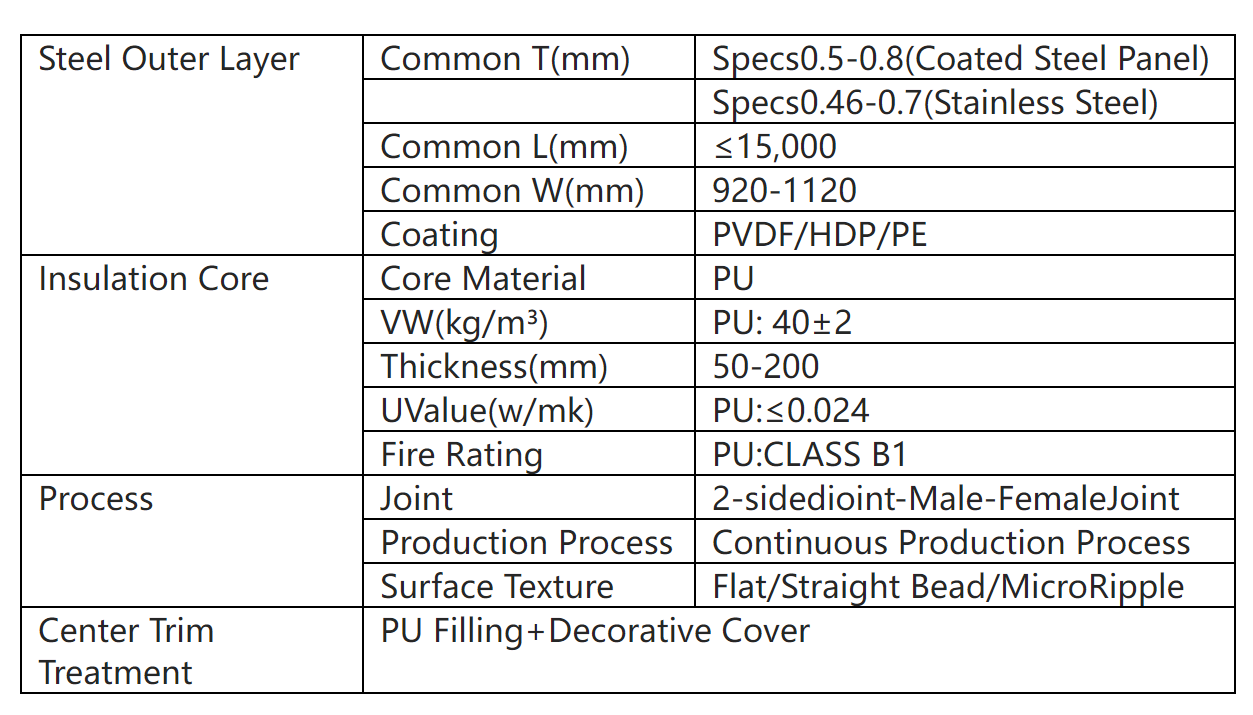

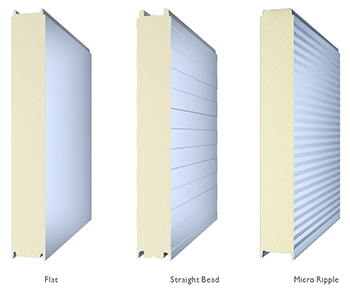

Product details

1. Product Parameters

2. Product Characteristics

– Core material adopts a new generation of rigid PU PIR foam composite material system to effectively block heat conduction, thus achieving excellent thermal insulation performance

– Reasonable joint design, good thermal insulation effect, superior mechanical properties. Excellent thermal insulation performance, high economic efficiency, reduce air loss and solar radiation heating, thereby reducing energy consumption and costs, reduce CO2 emissions, reduce building energy consumption

– Comply with the world’s major fire standards

– Low volatile organic compound (VOC) emissions, environmental protection and sustainability.

3. Production lines

The COLORSPAR® line developed by Wiskind boasts its system size as the most significant advantage. A 24-meter device can meet the manufacturing time of up to 24 meters, while a 30-meter device guarantees that it does not exceed the three-hour process requirement, resulting in improved product stability.

4. Product Project Cases

The core materials utilized in sandwich panels play a crucial role in energy conservation and thermal insulation. Polyurethane foam exhibits excellent insulating properties due to its low conductivity, thereby enabling the production of thinner panels and maximizing living space within buildings. Owing to these exceptional attributes, polyurethane has emerged as an ideal and indispensable filling material for sandwich panel manufacture.

The PU sandwich panel boasts exceptional insulation performance. We offer a range of thickness options, from 40mm to 250mm, allowing customers to select the most suitable thickness for their specific requirements. Our production line is equipped with OMS brand machinery imported from Italy, spanning a total length of 320 meters and featuring a track length of 42 meters, enabling extended sheet formation time. For production, we utilize BASF materials and cutting-edge technology.

We utilize a state-of-the-art PU PIR pentane foam B1 foam as the core material, ensuring our production of PIR PUR PU polyurethane insulation wall sandwich panels exhibit exceptional thermal insulation and fire-resistant properties. With high temperature stability and fire rating, zero freon emissions, as well as energy-saving and environmentally friendly features, these panels find extensive applications in industrial buildings and cold storage projects.

The core materials used in sandwich panels are of great significance for energy saving and heat insulation. Polyurethane foam provides high insulation properties for buildings with its low conductivity. In addition, it offers the opportunity to gain more living space in buildings by allowing for the manufacture of thinner panels. Due to these superior properties, polyurethane has become an ideal and indispensable filling material in sandwich panel manufacturing.

Reviews

There are no reviews yet.